SOLUTIONS FOR DOSING GRANULES INTO BAGS, CANS & JARS

From 1-channel scales to semi- and fully automated systems

Level 1 – Basic

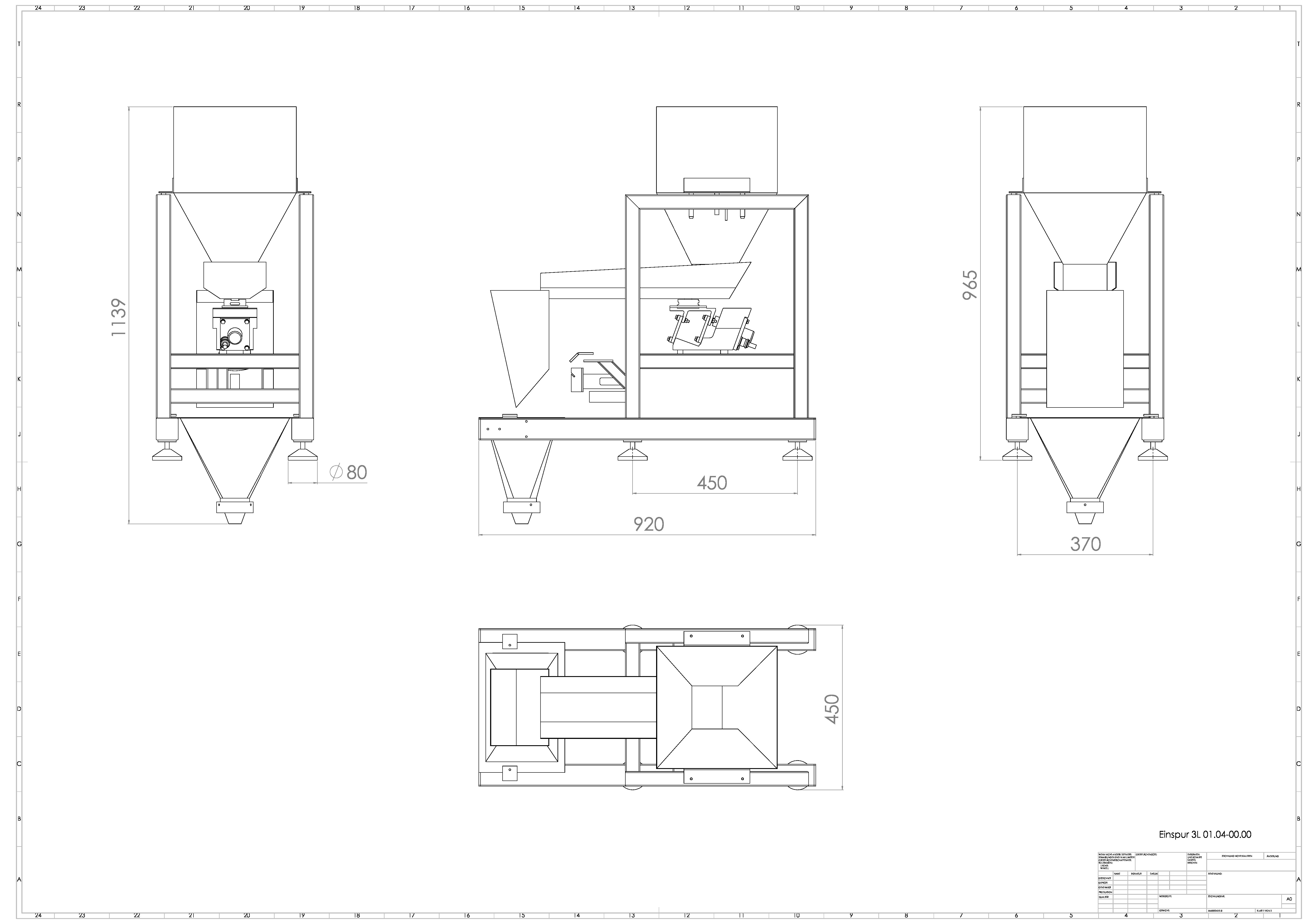

Scale – JMT1CH3L

- Consisting of: 1-Channel scale

-

Volume weighing hopper: 3L

-

Filling range: 50~1000g

Read more …

DOSING/FILLING SCALE 1-channel JMTRONIC

For the precise filling of bulk goods, powders and granules such as tea, coffee beans and spices, salt, sugar, flour, dried fruit, rice, fish food, etc.

As a standalone version for manual filling or automated combined with our vacuum conveyor system for automatic feeding and a JMTronic packaging machine.

The standalone version can be combined as a table model or optionally on a steel frame painted in RAL or made of stainless steel. The frame is mobile with lockable castors.

The standard weighing hopper has a volume of 3 liters. Depending on the product, you can therefore fill from 1g to approx. 3kg or 3L per cycle. The accuracy also depends on the product and the achievable, uniform product flow. The machine itself can weigh to an accuracy of 0.1g. You will receive a free test from us with your material, send it to us. We can then show you on video exactly what quantities and accuracy can be reliably achieved. Roasted coffee beans – accuracy 1-2g, approx. 500 drops 500g/h, corresponds to approx. 6-7sec per 500g of coffee beans. 250g approx. 4-5sec and 1000g approx. 10-12 sec. In manual operation, the discharge is triggered by a foot pedal. The signal is transmitted in conjunction with a packaging machine.

The electronics and weighing technology are housed in a control cabinet, the control system is from SIEMENS, as are the components. The software was produced by us and optimized for the scale. Over 100 recipes can be stored in which all the machine parameters are saved. As an option, you can integrate remote maintenance via a router, so we can always support you very quickly. All weighing processes can be logged and printed out to ensure traceability.

We would be happy to provide you with an individual offer – send us approx. 5-10l of the product to be transported for a free assessment. We are very familiar with products such as coffee (ground, raw and roasted), rice, tea and similar granulates. Other equipment such as product feeders, bag sealers etc. are also available from us to suit your individual requirements.

Suitable materials & packaging

Level 2 – Performance

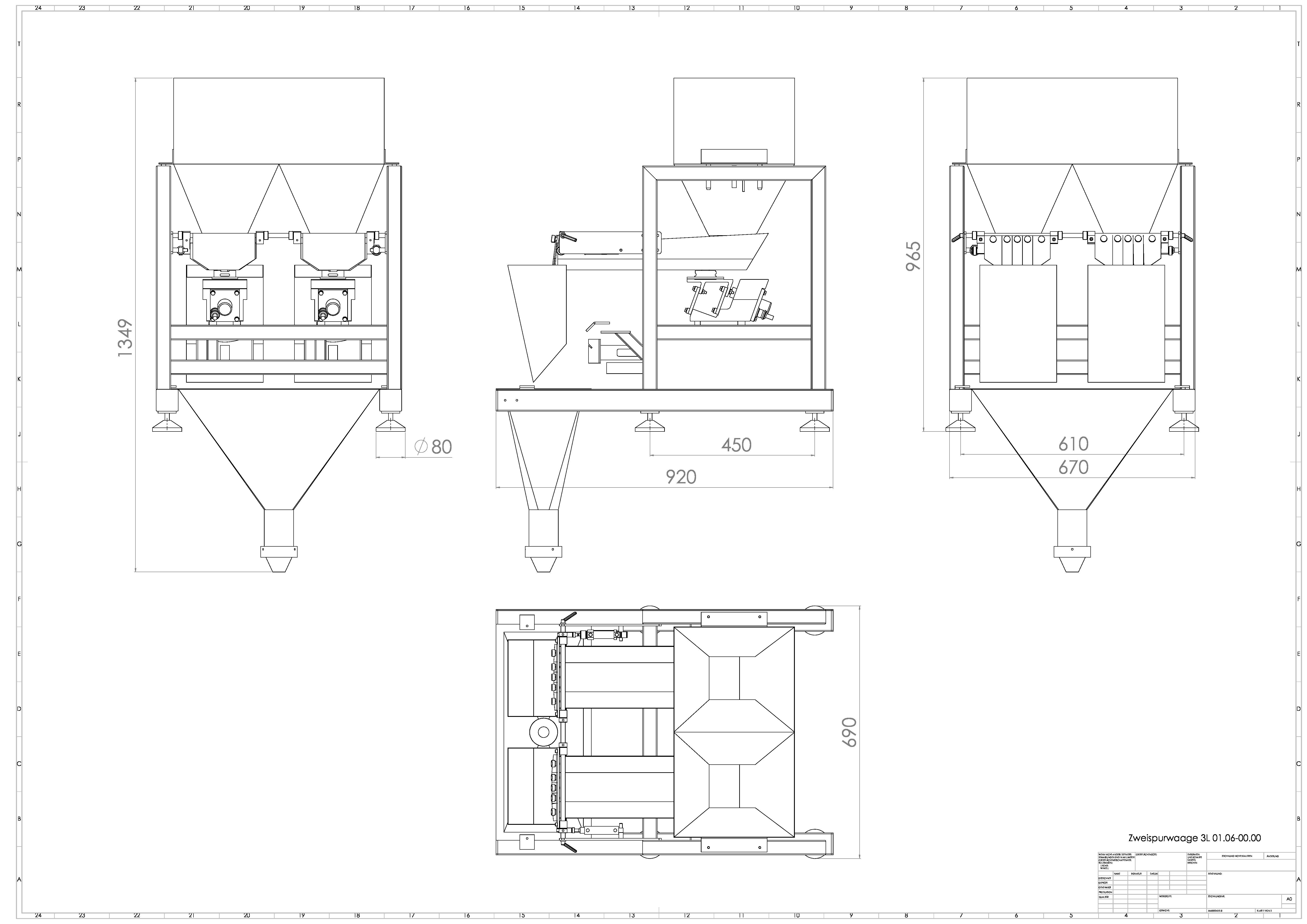

Scale – JMT2CH3L

- Consisting of: 2-Channel scale

-

Volume weighing hopper: 2x3L

-

Filling range: 50~1000g

Read More …

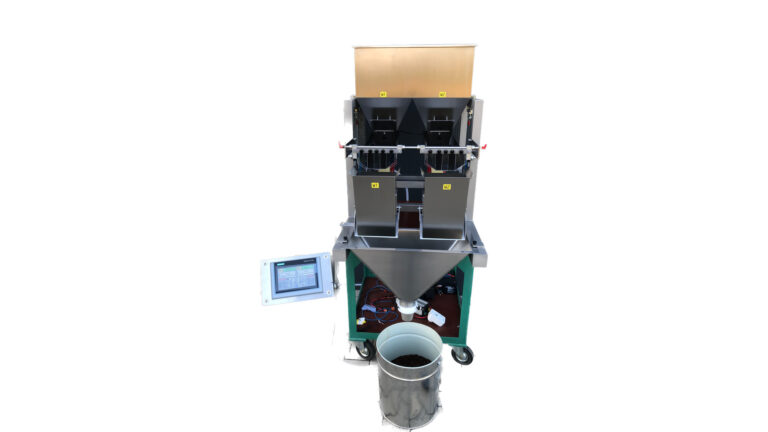

DOSING/FILLING SCALE 2 channel JMTRONIC

For the precise filling of bulk goods, powders and granules such as tea, coffee beans and spices, salt, sugar, flour, dried fruit, rice, fish food, etc.

As a standalone version for manual filling or automated combined with our vacuum conveyor system for automatic feeding and a packaging machine from JMTronic. This system is usually combined with a packaging machine – but can also be operated manually at any time – flexibility and production are guaranteed! Available as a tabletop model or optionally on a steel frame painted in RAL or made of stainless steel. The frame is mobile with lockable castors.

The standard weighing hoppers have a volume of 3 liters (up to 5 liters optional). Depending on the product, you can therefore fill from 1 g to approx. 3 kg or 3 liters per cycle.

Double cycle or ultra-fine dosing?

Our 2-channel weigher can do both! Depending on the product and requirements, we can also combine a coarse and fine track for maximum accuracy, down to 0.1g! Or both channels work alternately, so the 2nd channel weighs with a time delay alternating with the 1st channel = double speed. Our multi-channel system can be designed as a modular system with up to 8 tracks! Accuracy and speed are no longer in conflict!

If you are interested, send us your goods to be weighed and we will test it for you free of charge. We can then show you on video exactly what quantities and accuracy can be reliably achieved. Roasted coffee beans – accuracy 1-2g, approx. 800 drops 500g/h, corresponds to approx. 3-4 sec per 500g of coffee beans. 250g approx. 2-3sec and 1000g approx. 6-8 sec. In manual operation, the discharge is triggered by a foot pedal. The signal is transmitted in conjunction with a packaging machine. The full capacity can usually only be realized with 2 channels in parallel with a packaging machine.

We offer various options for refilling sufficient product. We transport most products with a vacuum conveyor system, which refills the product fully automatically (see separate product description).

For bridging and difficult material, we can optionally design the system with a vibration hopper. In addition, we have various options for filling difficult material reliably.

For special applications in the pharmaceutical industry, we can offer AISI 316L stainless steel, mirror polished RA0.4-0.6 for parts in contact with the product. The machine can also be sealed to the outside and equipped with a suction device.

The electronics and weighing technology are housed in a control cabinet, the control system is from SIEMENS, as are the components. The software was produced by us and optimized for the scale. Over 100 recipes can be stored in which all machine parameters are saved. As an option, you can integrate remote maintenance via a router, so we can always support you very quickly. All weighing processes can be logged and printed out to ensure traceability.

We would be happy to provide you with an individual offer – send us approx. 5-10l of the product to be transported for a free assessment. We are very familiar with products such as coffee (ground, raw and roasted), rice, tea and similar granulates. Other equipment such as product feeders, bag sealers etc. are also available from us, individually tailored to your requirements.

Suitable materials & packaging

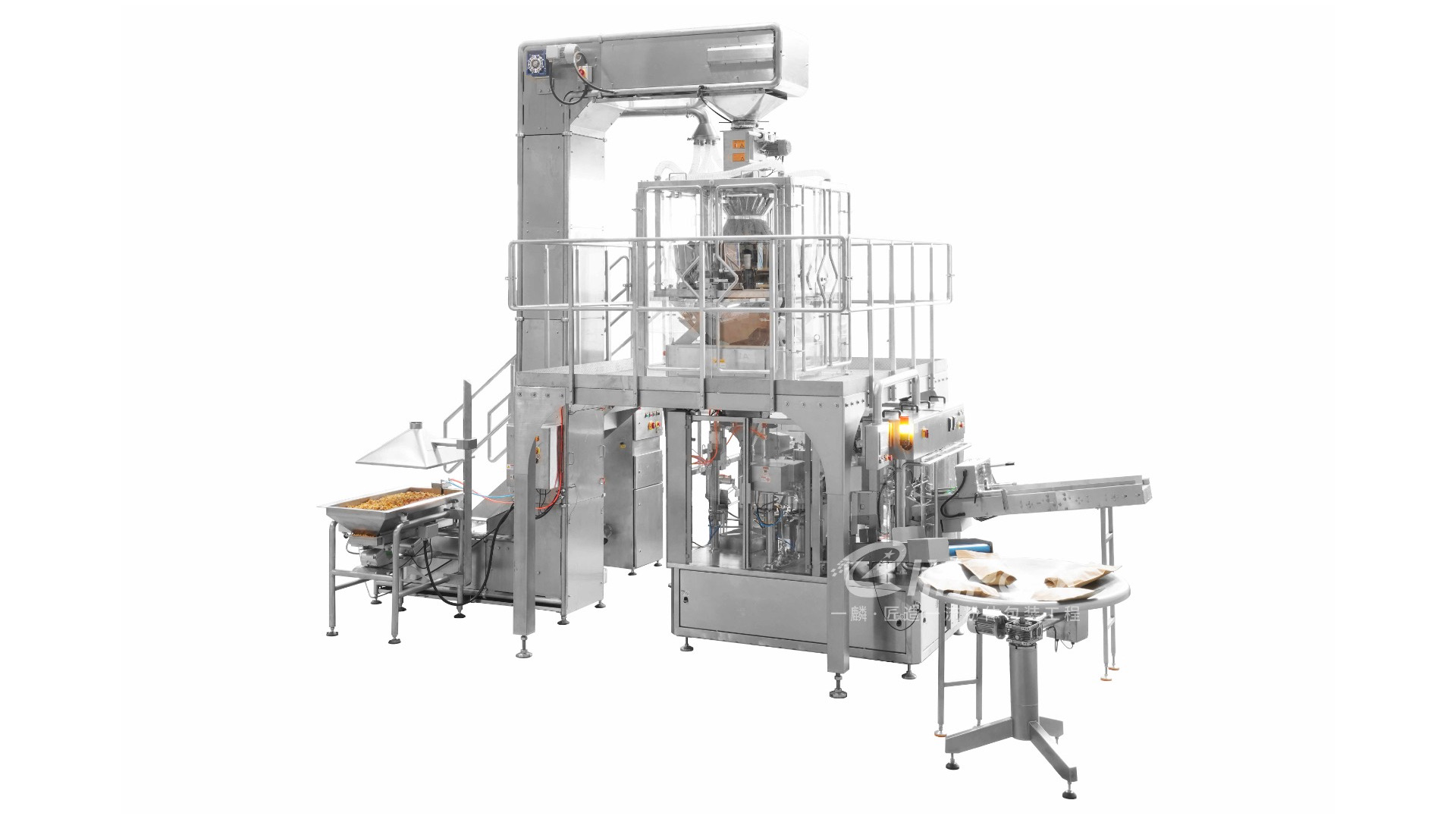

Level 3 – Full automation basis

Packaging-line – JMT-Line430G

- Consisting of: Bucket conveyor + dosing machine + packaging machine + unloading belt + collecting table

- Individually configurable

- Information on request

Read More …

Bucket conveyor:

- Carrying capacity: 0-10 m³/h

- Discharging height: 3400mm

- Hopper volume: 650x650mm

- Power: 1-phase, 220V, 50Hz, 0,75 KW

- Frame bending: on the outside instead of inside, easy for clean, no dead angle

- Inverter: 0,75 KW

- Bearing: on the outside for easy dismantle

Scale: JMT2H4,5L

- Volume weighing hopper: 4,5L

- Filling range: 50~3000g

- Filling accuracy: ±0,3-3,0g

- Filling speed: 10~20 bars/min

- Prescriptions safe: 20

- Power: AC230/50/60Hz/1-phase, 1,2 KW

- Dimensions in mm: 920(l) x 800(w) x 890(h)

- Material: SS304(1.4301)

Packaging Machine: JMT-430G:

-

- For bag type: D (D1, D2)

- Speed: 4~6 bars/min

- Bag size: width: 80~200mm, hight: 200~430mm, Side gusset wide: ≥60mm (30+30mm)

- Power: AC220~415V, 50/60Hz, 3-phase, 2,25 KW

- Air-consume: ≤150 NL/min, 0,65 Mpa

- Machine weight: 390Kg

- Dimensions in mm: 1800(l) x 600(w) x 1500(h)

- Material: SS304(1.4301)

Option to handle bag type A, B, C:

- Speed: 6~12 bars/min

- Bag size: width: 100~240mm, hight: 150~430mm

Configuration:

- PLC: Japan Panasonic

- HMI panel: Kinco

- Pneumatic: Taiwan Airtac

- Main electrics: Germany Schneider, Eaton, Omron, Japan Panasonic etc.

- Mini conveyor: Discharge belt

JMT-Collection-Table:

- Model: PCT-1200

- Diameter: Φ1200mm

- Speed: ≤160 bags/min

- Inverter: Germany Schneider

- Variable speed controller: Germany Schneider

- Power: 1-phase, 220V, 50Hz, 0,18 KW

- Machine weight: 80Kg

- Material: SS304(1.4301)

Suitable materials & packaging

Level 4 – Full automation Performance

Packaging-line – JMT-MULTI-ROUND8

- Consisting of: Bucket conveyor + dosing machine + packaging machine + unloading belt + collecting table

- Individually configurable

- Information on request

Suitable materials & packaging

Our solutions for you

Contact us

JMTronic

Dosing & filling scales manufacturer

Ralf Diebold-Jäger

Am Untergrün 3

79232 March-Buchheim

Phone: +49 (0)7665 9426470

E-Mail: contact@jm-tronic.com